Application Center VerTec

| Deutsch |

Application Center VerTec

Novel materials and production processes of components applied in process engineering – VerTec

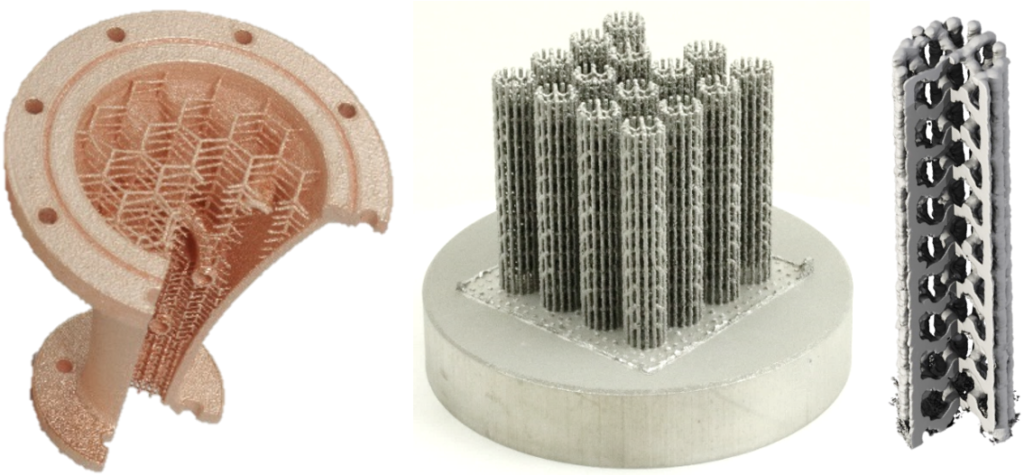

Components used in chemical process engineering applications such as reactors, mixers and heat exchangers are key elements which determine the efficiency and safety of chemical processes. These often highly complex devices are subject to mechanical, thermal and corrosive stress. A particular problem in manufacturing such components is the relatively small number of units often in combination with materials that are difficult to machine. Furthermore, conventional manufacturing methods do not allow for a completely free three-dimensional design of the equipment. Here, additive manufacturing is a powerful tool for the production of highly complex tailor-made components for use in chemical process engineering (see the following figure).

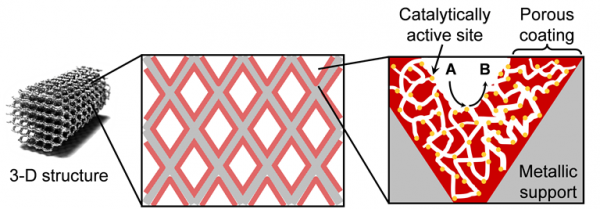

The Technology Transfer Center VerTec aims for a holistic approach. Computer-aided modelling and simulation allow for the identification of almost ideal geometries. These structures are manufactured by Selective Electron Beam Melting (SEBM) of metal powder. SEBM enables near-net-shaped manufacturing of metals (e.g., titanium alloys, nickel base alloys, titanium aluminide, cobalt chrome or copper). Currently, numerous SEBM machines are available at the Technology Transfer Center VerTec (Freemelt ONE, Arcam Q10 plus, Arcam A2X).

Using appropriate coating technologies, the surface can be functionalized with regard to catalytic activity. Finally, application tests are conducted to demonstrate the superior performance compared to state of the art equipment.

Partners

Selected publications

- Wolf T., Fu Z. and Körner C., Selective electron beam melting of an aluminum bronze: Microstructure and mechanical properties. Materials Letters, 2019. 238: p. 241-244 DOI: https://doi.org/10.1016/j.matlet.2018.12.015.

- Heßelmann C., Wolf T., Galgon F., Körner C., Albert J. and Wasserscheid P., Additively manufactured RANEY®-type copper catalyst for methanol synthesis. Catalysis Science & Technology, 2020. 10(1): p. 164-168 DOI: https://doi.org/10.1039/C9CY01657K.

- Moioli E., Schmid L., Wasserscheid P. and Freund H., Kinetic modelling of reactions for the synthesis of 2-methyl-5-ethyl pyridine. Reaction Chemistry & Engineering, 2021 DOI: https://doi.org/10.1039/D1RE00085C.

- Geißelbrecht M., Mrusek S., Müller K., Preuster P., Bösmann A. and Wasserscheid P., Highly efficient, low-temperature hydrogen release from perhydro-benzyltoluene using reactive distillation. Energy & Environmental Science, 2020. 13(9): p. 3119-3128 DOI: https://doi.org/10.1039/D0EE01155J.

- Dürr S., Zilm S., Geißelbrecht M., Müller K., Preuster P., Bösmann A. and Wasserscheid P., Experimental determination of the hydrogenation/dehydrogenation-Equilibrium of the LOHC system H0/H18-dibenzyltoluene. International Journal of Hydrogen Energy, 2021. 46(64): p. 32583-32594 DOI: https://doi.org/10.1016/j.ijhydene.2021.07.119.

- Littwin G., Röder S. and Freund H.r., Systematic Experimental Investigations and Modeling of the Heat Transfer in Additively Manufactured Periodic Open Cellular Structures with Diamond Unit Cell. Industrial & Engineering Chemistry Research, 2021 DOI: https://doi.org/10.1021/acs.iecr.0c06210.

- Pistor J., Breuning C. and Körner C., A Single Crystal Process Window for Electron Beam Powder Bed Fusion Additive Manufacturing of a CMSX-4 Type Ni-Based Superalloy. Materials, 2021. 14(14): p. 3785 DOI: https://doi.org/10.3390/ma14143785.

- Wormser M., Kiefer D.A., Rupitsch S.J. and Körner C., Comparison of Transmission Measurement Methods of Elastic Waves in Phononic Band Gap Materials. Materials, 2021. 14(5): p. 1133 DOI: https://doi.org/10.3390/ma14051133.

- Reith M., Franke M., Schloffer M. and Körner C., Processing 4th generation titanium aluminides via electron beam based additive manufacturing–characterization of microstructure and mechanical properties. Materialia, 2020. 14: p. 100902 DOI: https://doi.org/10.1016/j.mtla.2020.100902.

- Bieske J., Franke M., Schloffer M. and Köerner C., Microstructure and properties of TiAl processed via an electron beam powder bed fusion capsule technology. Intermetallics, 2020. 126: p. 106929 DOI: https://doi.org/10.1016/j.intermet.2020.106929.