Research

| Deutsch |

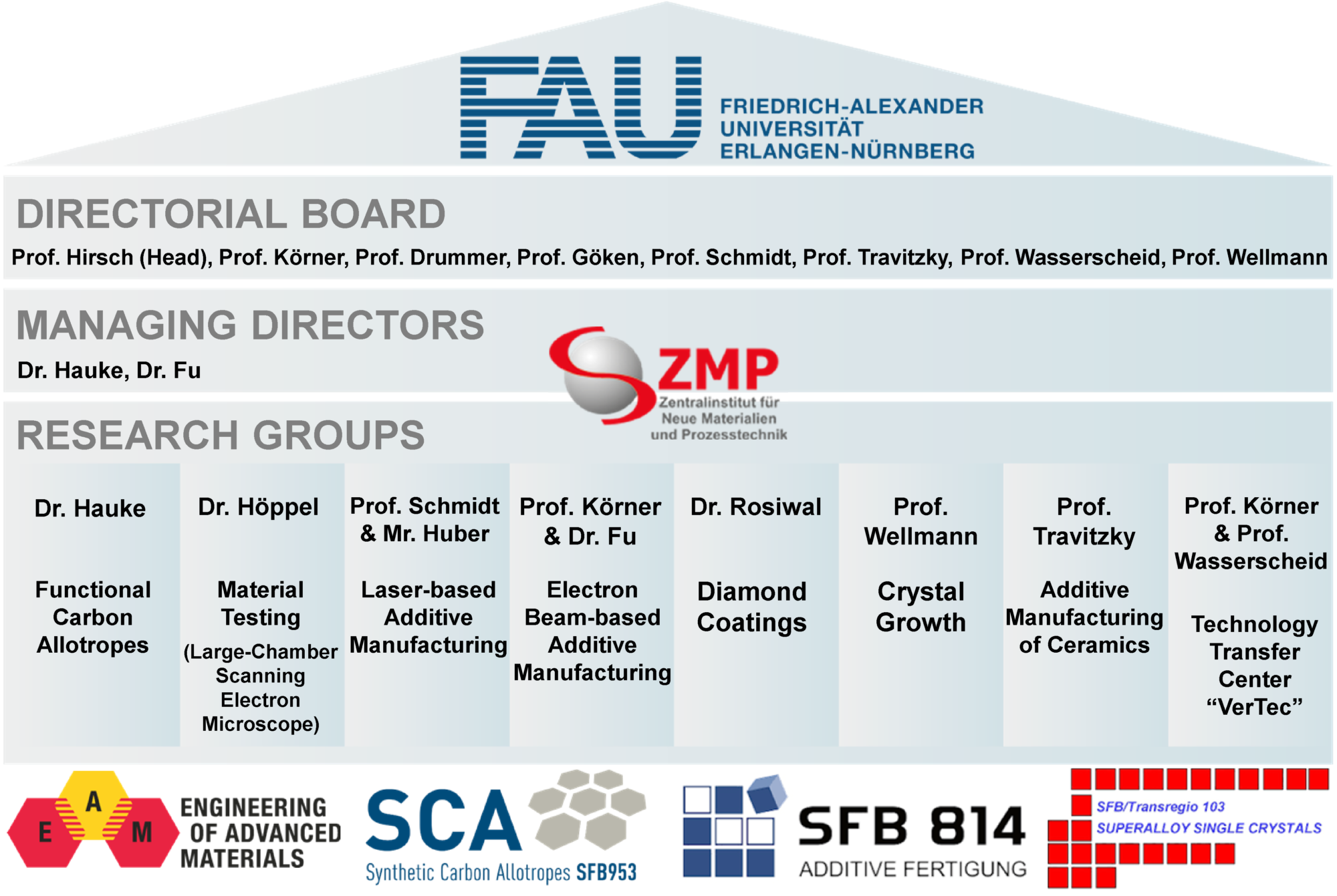

The Center of Advanced Materials and Processes (ZMP) of the University Erlangen-Nürnberg is an interdisciplinary research facility, founded in 2006 with the objective to support multidisciplinary research in the field of materials science, mechanical engineering, chemistry and physics. The focus of research activities is on the development of novel materials concepts and respective manufacturing methods. Main goal is the transfer and development of basic research ideas, which evolve from the institutes involved in ZMP, from the lab to the prototype stadium. The considered range of materials includes light metals, high temperature alloys, ceramics and carbon. Typical process routes include different additive manufacturing processes, rapid prototyping technologies or powder injection molding. These technologies are accompanied by modern methods for microstructural characterization and component analysis.

involved in ZMP, from the lab to the prototype stadium. The considered range of materials includes light metals, high temperature alloys, ceramics and carbon. Typical process routes include different additive manufacturing processes, rapid prototyping technologies or powder injection molding. These technologies are accompanied by modern methods for microstructural characterization and component analysis.

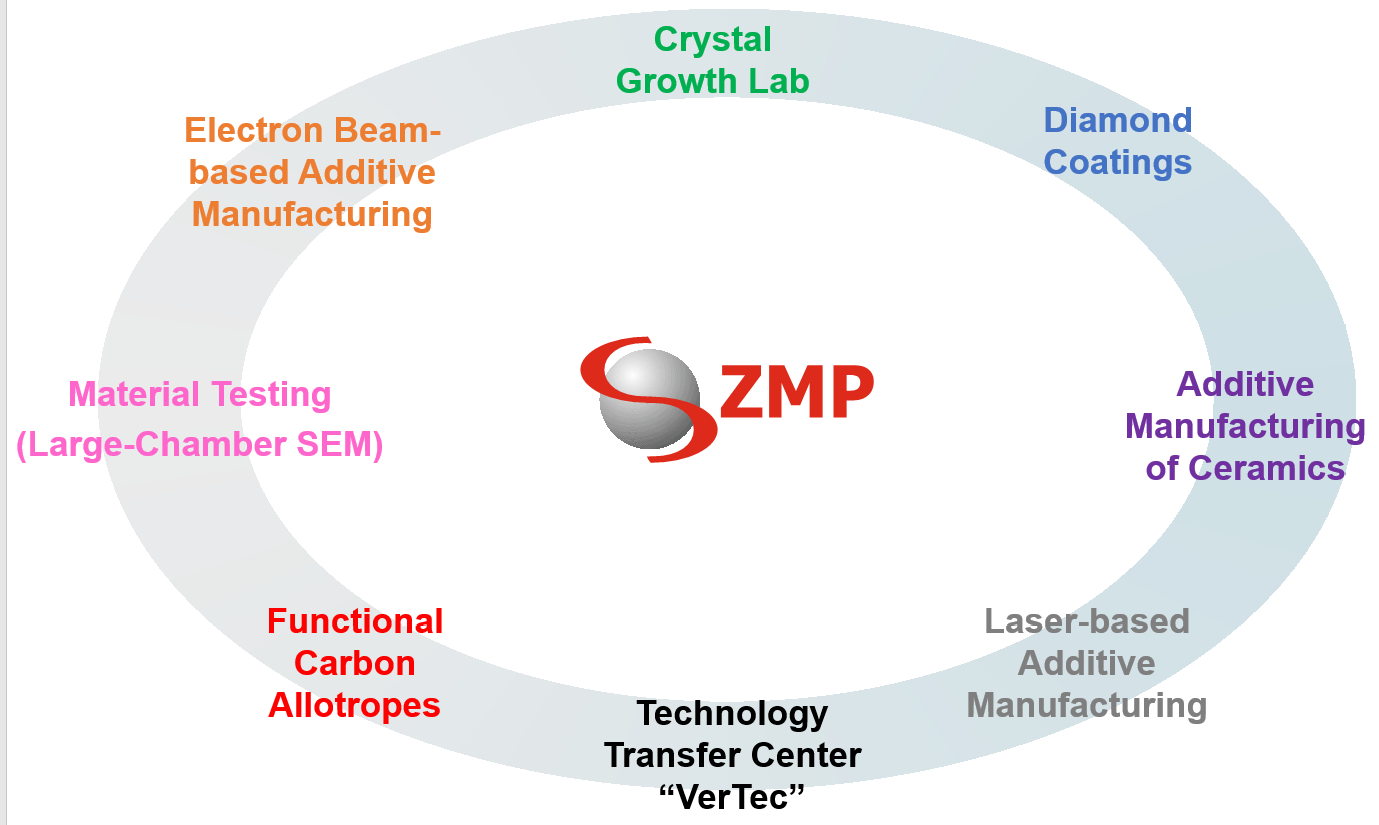

Currently, the research at ZMP can be divided into seven research groups: Crystal Growth Lab (Prof. Wellmann), Electron beam-based Additive Manufacturing (Prof. Körner and Dr. Fu), Functional Carbon Allotropes (Prof. Hirsch and Dr. Hauke), Additive Manufacturing of Ceramics (Prof. Travitzky), Non-Destructive Testing of Materials and Devices (Prof. Göken and Dr. Höppel), Laser-based Additive Manufacturing (Prof. Schmidt and Mr. Bartels) and Diamond Coatings (Prof. Rosiwal). Additionally, the Technology Transfer Center VerTec (Prof. Körner and Prof. Wasserscheid) addresses novel materials and production processes of components applied in process engineering. Due to the interdisciplinary focus of the respective research groups at ZMP, manifold scientific advances were achieved.

Partners:

Institute of Chemical Reaction Engineering (Prof. Wassershed)

Institute of Metals Science and Technology (Prof. Körner)

Neue Materialien Fürth GmbH

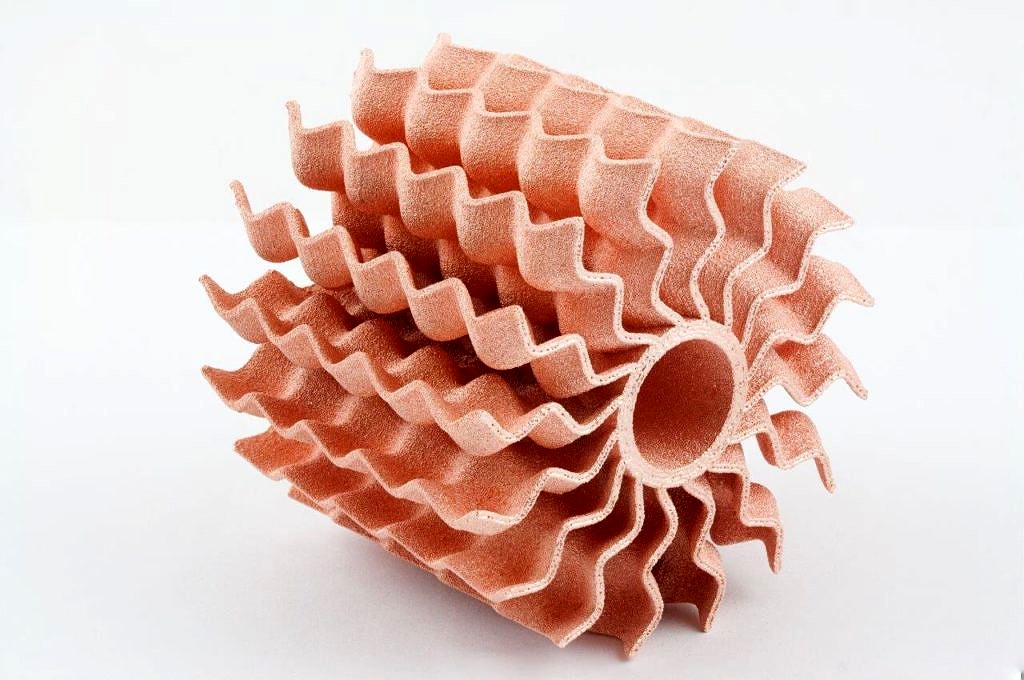

The Technology Transfer Center VerTec develops tailor-made components, e.g. for medical, energy or process engineering applications. The focus is on Additive Manufacturing of components using Selective Electron Beam Melting. A subsequent coating of the structure with catalytically active materials is possible.

The Technology Transfer Center VerTec develops tailor-made components, e.g. for medical, energy or process engineering applications. The focus is on Additive Manufacturing of components using Selective Electron Beam Melting. A subsequent coating of the structure with catalytically active materials is possible.

Partners:

Institute of Metals Science and Technology (Dr. Rosiwal)

DiaCCon GmbH

The Diamond Coating group works on Hot-Filament Chemical Vapor Deposition of diamond thin films on metallic and ceramic substrates. Applying a recently developed high-temperature interlayer, the adherence of diamond coatings on steel substrates is improved. Additionally, the scale-up of the process towards higher growing rates and higher areas of deposition is addressed.

The Diamond Coating group works on Hot-Filament Chemical Vapor Deposition of diamond thin films on metallic and ceramic substrates. Applying a recently developed high-temperature interlayer, the adherence of diamond coatings on steel substrates is improved. Additionally, the scale-up of the process towards higher growing rates and higher areas of deposition is addressed.

More details…

Institute of Glass and Ceramics (Prof. Travitzky)

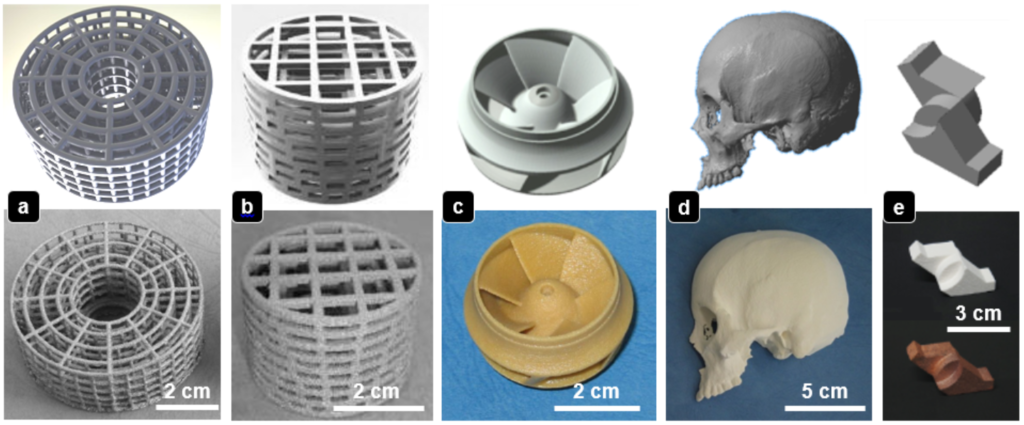

The main objective of the Additive Manufacturing of Ceramics at the University of Erlangen-Nuernberg is to obtain fundamental knowledge of the use of processing routes that can result in fabrication of parts made of ceramic and ceramic/metal composites. At ZMP highly complex ceramic structures are produced applying various Additive Manufacturing processes such as Laminated Object Manufacturing (LOM) with preceramic papers, Robocasting, Fused Deposition Modeling (FDM), Selective Laser Curing (SLC) or Three-Dimensional Printing (3D-Printing).

The main objective of the Additive Manufacturing of Ceramics at the University of Erlangen-Nuernberg is to obtain fundamental knowledge of the use of processing routes that can result in fabrication of parts made of ceramic and ceramic/metal composites. At ZMP highly complex ceramic structures are produced applying various Additive Manufacturing processes such as Laminated Object Manufacturing (LOM) with preceramic papers, Robocasting, Fused Deposition Modeling (FDM), Selective Laser Curing (SLC) or Three-Dimensional Printing (3D-Printing).

More details…

Partners:

Institute of Metals Science and Technology (Prof. Körner and Dr. Fu)

Neue Materialien Fürth GmbH

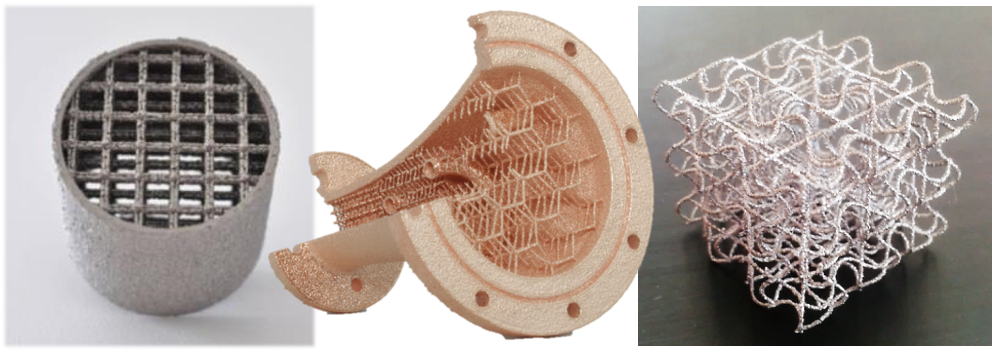

Starting from metal powder and CAD data, Selective Electron Beam Melting (SEBM) enables near-net-shape manufacturing of almost any 3D-geometry. Processing under vacuum atmosphere ensures high material purity and quality. Thus even high melting or reactive materials such as titanium, copper or nickel-base alloys can be handled.

Starting from metal powder and CAD data, Selective Electron Beam Melting (SEBM) enables near-net-shape manufacturing of almost any 3D-geometry. Processing under vacuum atmosphere ensures high material purity and quality. Thus even high melting or reactive materials such as titanium, copper or nickel-base alloys can be handled.

More details…

Institute of Organic Chemistry II (Prof. Hirsch and Dr. Hauke)

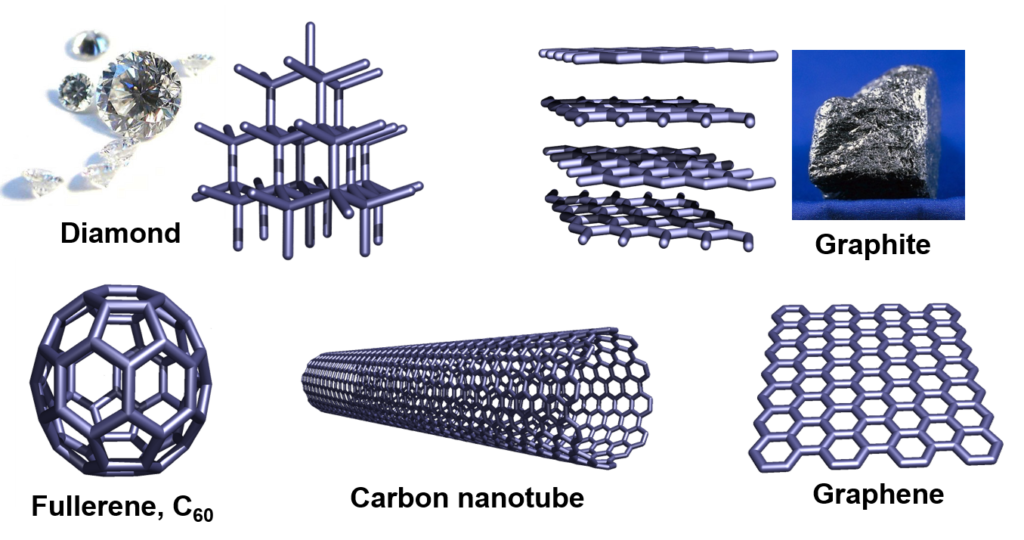

The ubiquitous element carbon is the scientific base of the “Carbon Allotropes” research group. Next to the common carbon modifications graphite and diamond, the synthetic carbon allotropes – fullerenes, carbon nanotubes and graphene – are in the focus of current material research.

The ubiquitous element carbon is the scientific base of the “Carbon Allotropes” research group. Next to the common carbon modifications graphite and diamond, the synthetic carbon allotropes – fullerenes, carbon nanotubes and graphene – are in the focus of current material research.

More details…

Institute of Photonic Technologies (Prof. Schmidt)

The working group’s focus is on research and development of laser-based generative manufacturing processes, e.g. Selective Laser Melting (SLM) of metals in the powder bed or laser-based powder deposition welding. Laser melting of metals in the powder bed is addressed in detail within the Collaborative Research Center 814 – Additive Manufacturing (supported by the German Research Foundation, DFG).

The working group’s focus is on research and development of laser-based generative manufacturing processes, e.g. Selective Laser Melting (SLM) of metals in the powder bed or laser-based powder deposition welding. Laser melting of metals in the powder bed is addressed in detail within the Collaborative Research Center 814 – Additive Manufacturing (supported by the German Research Foundation, DFG).

More details…

Institute of General Material Properties (Prof. Göken and Dr. Höppel)

The focus of the working group “Materials Testing” is on in-situ testing of various material systems. The Large-Chamber Scanning Electron Microscope (LC-SEM) allows for mechanical materials testing and microstructural characterization at the same time. Additionally, non-destructive materials testing of large components is possible.

The focus of the working group “Materials Testing” is on in-situ testing of various material systems. The Large-Chamber Scanning Electron Microscope (LC-SEM) allows for mechanical materials testing and microstructural characterization at the same time. Additionally, non-destructive materials testing of large components is possible.

Chair of Materials for Electronics and Energy Technology (Prof. Wellmann)

The Crystal Growth Lab @ FAU headed by Prof. Dr.-Ing. Peter Wellmann is located at the Electronic Materials and Energy Technology (i-meet) division of the Materials Department (Friedrich-Alexander Universität Erlangen-Nürnberg) and at the Institute of Advanced Materials and Processes (Zentrum für neue Materialien und Prozesstechnik, ZMP). The research activities are devoted to modern topics in semiconductor technology and include crystal growth, epitaxy and characterization of various electronic materials with special emphasis on wide bandgap semiconductors.

The Crystal Growth Lab @ FAU headed by Prof. Dr.-Ing. Peter Wellmann is located at the Electronic Materials and Energy Technology (i-meet) division of the Materials Department (Friedrich-Alexander Universität Erlangen-Nürnberg) and at the Institute of Advanced Materials and Processes (Zentrum für neue Materialien und Prozesstechnik, ZMP). The research activities are devoted to modern topics in semiconductor technology and include crystal growth, epitaxy and characterization of various electronic materials with special emphasis on wide bandgap semiconductors.